BizLineScanTool

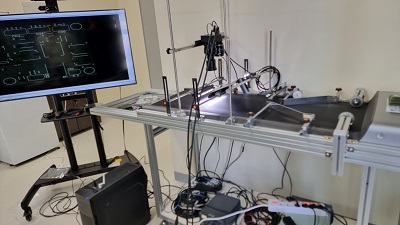

The line scan camera system is a system that precisely inspects a subject moving through a high-speed conveyor belt in real time.

It is a key surface inspection technology that enables real-time identification and immediate response to defects

in materials such as plastic, paper, film and metal.

-

Improve work accuracy

You can increase the accuracy of tasks that require precision.

-

Expanding the scope of automation work

AI can learn on its own and expand its scope of work.

-

Improving business performance

Work performance can be improved by concentrating on work in high value-added fields of employees.

Features of line scan camera technology

-

High speed

BizTrigger works without problems between 1Km/h and 6Km/h

-

Real-time

When the object is detected, image capture, error determination, and result feedback are performed in real time

-

high resolution

Provided as a horizontal 4096 pixels image

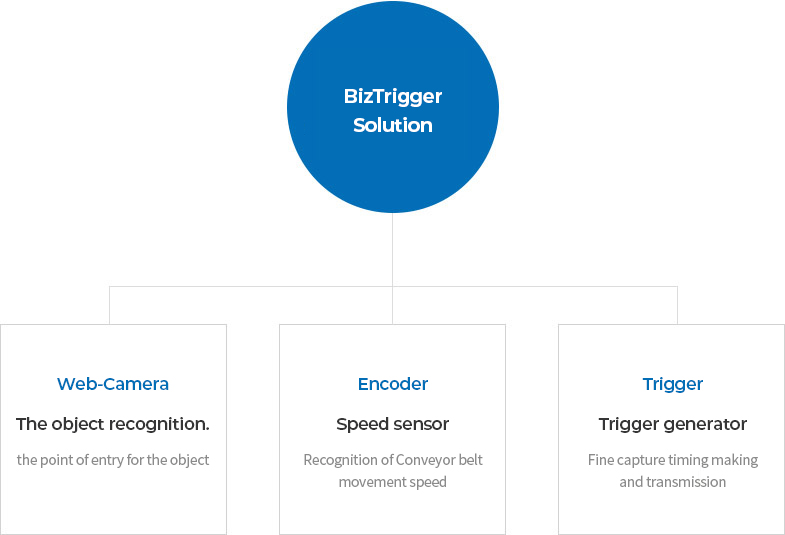

BizTrigger Part

Scroll left and right to view the entire image.

The line scan camera system needs to scan a subject moving at high speed in real time, but it should be considered that the subject is supplied irregularly.

Trigger technology is a technology that detects the entry of an object to be inspected and instructs the line scan camera to shoot.

This technology is a complex technology that installs a line scan camera and web camera to generate a trigger and utilizes an encoder

to detect the speed of a conveyor belt.

Features of trigger technology

-

Image recognition

A technology that recognizes the entry of an object using a high-performance web-camera because it is difficult to detect a thin object with an infrared sensor or a touch sensor.

-

Encoder

Technology to detect the speed of the conveyor belt and provide speed information to the line scan camera to adjust capturing speed in real time

-

Trigger

A technology that marks the starting point of the operation of photographing a moving object with a line scan camera and saving it as an image.