BizMonitor-ET

Environment/temperature monitoring of process/equipment

BizMonitor is an integrated solution for real-time monitoring of the manufacturing process and

office environment. It measures ultrafine dust (PM 1.0/PM 2.5), fine dust (PM 10), temperature, humidity, CO2, VOC, etc.

using air quality sensors with 6 equipment temperature sensors (-20℃~300℃), and enables real-time monitoring and big data provision.

-

Real-time Data Collection and Analysis

BizMonitor collects sensor data and all data generated during the manufacturing process in real time,

Using various analysis techniques such as statistical analysis, prediction algorithm, and artificial intelligence algorithm,

and it make operational/management processes tailored to each user. -

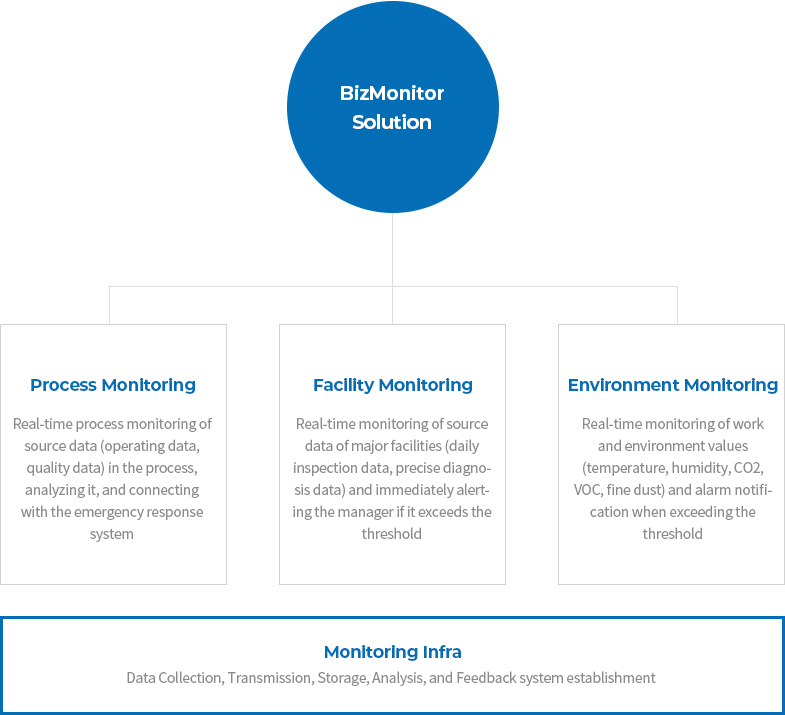

Process and facility total monitoring system

BizMonitor provides real-time process monitoring, inquiry and analysis, and emergency response system by analyzing 4 types of source data (operation data, daily inspection data, precision diagnosis data, quality data) using data analysis S/W.

-

Environment Monitoring

We research and develop precision sensors and monitoring systems suitable for fine dust and indoor air quality measurement. Using 'Systronics air quality sensor', it measures ultrafine dust (PM 1.0 / PM 2.5), fine dust (PM 10), temperature and humidity, CO2, VOC, etc. And Integrated monitoring and control it with remote management system It is recommended for schools, hospitals, public facilities, and precision manufacturing processes where fine dust emission is high or indoor air quality management is important

Target and Range of Environment Monitoring

| temperature range | -20 ~ 80℃(±0.5℃) |

| humidity range | 0 ~ 99% RH(±3% RH) |

| Co₂ range | 0 ~ 5,000ppm(±50ppm + 5%) |

| Voc range | 0 ~ 3 level |

| PM 1.0/ PM 2.5 range |

0~1000(±10ug/㎥ at 0~100ug/㎥±10% at 101~1,000ug/㎥) |

| PM 10 range | 0~1000(±25ug/㎥ at 0~100ug/㎥±25% at 101~1,000ug/㎥) |

| input power | 24VDC/VAC(18 ~ 36VDC) |

| current consumption | 0.15A at 24VDC |

| output port | 1 Port(relay, 5A 250Va/30VDC) |

| analog output port | 4 Port(0 ~ 10VDC) |

| communication port | 1 Port(RS-485) |

| operating temperature | -10 ~ 50℃ |

| operating humidity | 0 ~ 80%(without condensation) |

| storage temperature | -20 ~ 60℃ |

| product specifications | 710g / 137.0x173.9x76.0(㎜/WDH) |

| guide size | 10g/EA(4EA) |

Live monitoring (Table)

Monitoring System

| Item to be measured | Measures |

|---|---|

| carbon dioxide(Co₂) | 352 |

| Hazardous Substances(VOC) | 533 |

| Indoor humidity | 38 |

| Indoor temperature | 24 |

※As of 23:51:47 last measurement

| Fine dust | Measures |

|---|---|

| PM 1.0 | 10 |

| PM 2.5 | 10 |

| PM 10 | 10 |

| Device # | Measures |

|---|---|

| Device 1 | 38 |

| Device 2 | 38 |

| Device 3 | 20 |

| Device 4 | 2 |

| Device 5 | -15 |

| Device 6 | 25 |

Live monitoring (Graph)

BizMonitor-VC

Vibration/current monitoring of major equipment

The biggest risk factor in factory operation is downtime (the time when a machine or system cannot be operated due to a failure). If the factory is stopped even for a moment, it will lead to huge losses. Disasters such as power outages and earthquakes are difficult for humans to prevent, but equipment failures can be handled in advance by humans. Since most industrial equipment problems can be predicted in advance through vibration, temperature, and current monitoring, a predictive maintenance system was developed.

The vibration sensor senses vibration and temperature at user-defined time intervals and transmits them over a wireless mesh networking architecture with a range of up to two miles. This industrial IoT wireless vibration sensor samples 3-axis vibration data for 500 ms and then calculates RMS and maximum and minimum vibration readings. It is used in a solution that constantly monitors the status of major equipment through precise diagnosis of vibration and temperature.

Industrial IoT wireless AC current monitor sensor works with split core current sensor. Sample the current at a high data rate, calculate the RMS current value and send the radio transmission. It includes a clamp current sensor with a measuring range of 0-100A or 0-200A. Key features include an additional feature that detects a change in current at a user-defined sensing time interval and sends data if the current change is greater than the user-defined percentage of sensing change.

Features

-

Superior Application of superior

unique AI technologyCan apply AI technologies

in multiple areas. -

Flexible Flexible adaptability

to working environmentCan make automation even in

non-standard working environment. -

Easy Easy

developmentCan be developed easily

by the users. -

Fast Fast outcome

supportsProvides working and quality

information real-time basis.

BizMonitor Part

좌우 스크롤하시면 전체 이미지를 보실수 있습니다.

-

Factory

The factory supports real-time monitoring of the factory's working environment, and the accumulated big data is used as data for further analysis

-

Process and Facility

Preemptive response is possible by monitoring the condition of manufacturing processes and facilities and identifying abnormal signs in advance.

-

Office/Warehouse

Real-time monitoring and abnormal response system for offices or major warehouses where fine dust and indoor air quality management are important